regular guy

Basic User

- City

- Cameron

- State

- NC

I have read through this thread over and over again

https://www.cj-8.com/forum/showthre...quot-Postal-CJ8-Hardtop-idea&highlight=postal

It's been a long term plan to build a hard top out of two mail jeeps and a body tub fell in my lap for a price I couldn't turn down. I am in the process of finding the second one so in the mean time, I am trying to get the first one cut up and ready to fabricate. In my head, I am seeing more of a stretched CJ6 hard top. I want it to be modular so I don't have to take off a 500lb top. I would like for it to be able to be set up in a safari style where the top stays on, but the sides come off. I'd also like to add windows to either side of the rear door. I am keeping the rear barn door and will make it work. Haven't decided on keeping the original piano hinge or going with something else. There's more I'm sure but on to the pictures.

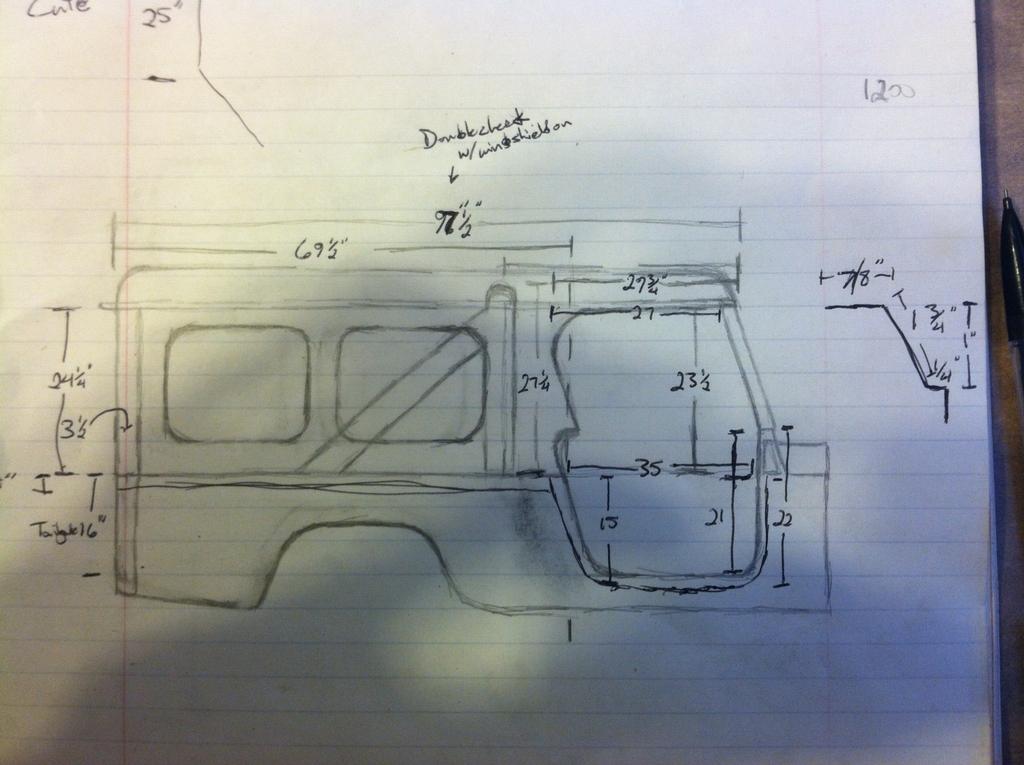

Here's the design layout with measurements

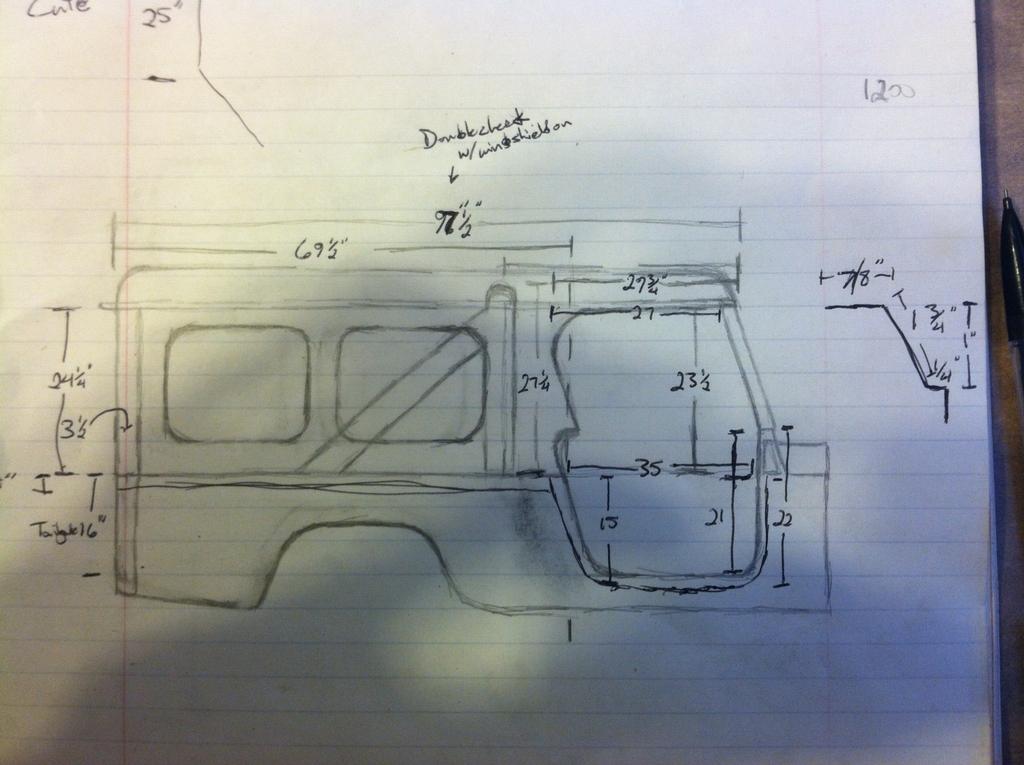

Here are the measurements of the donor top I've already got.

What the tub looked like when I picked it up.

All the windows pulled and ready for chopping

First side cut out. I am trying to save the rain gutter and have it attached to the top. I think that it will make an awesome mounting point with a little reinforcement for a roof rack later on.

Everything cut out except one little piece.

https://www.cj-8.com/forum/showthre...quot-Postal-CJ8-Hardtop-idea&highlight=postal

It's been a long term plan to build a hard top out of two mail jeeps and a body tub fell in my lap for a price I couldn't turn down. I am in the process of finding the second one so in the mean time, I am trying to get the first one cut up and ready to fabricate. In my head, I am seeing more of a stretched CJ6 hard top. I want it to be modular so I don't have to take off a 500lb top. I would like for it to be able to be set up in a safari style where the top stays on, but the sides come off. I'd also like to add windows to either side of the rear door. I am keeping the rear barn door and will make it work. Haven't decided on keeping the original piano hinge or going with something else. There's more I'm sure but on to the pictures.

Here's the design layout with measurements

Here are the measurements of the donor top I've already got.

What the tub looked like when I picked it up.

All the windows pulled and ready for chopping

First side cut out. I am trying to save the rain gutter and have it attached to the top. I think that it will make an awesome mounting point with a little reinforcement for a roof rack later on.

Everything cut out except one little piece.