- City

- Denver

- State

- CO

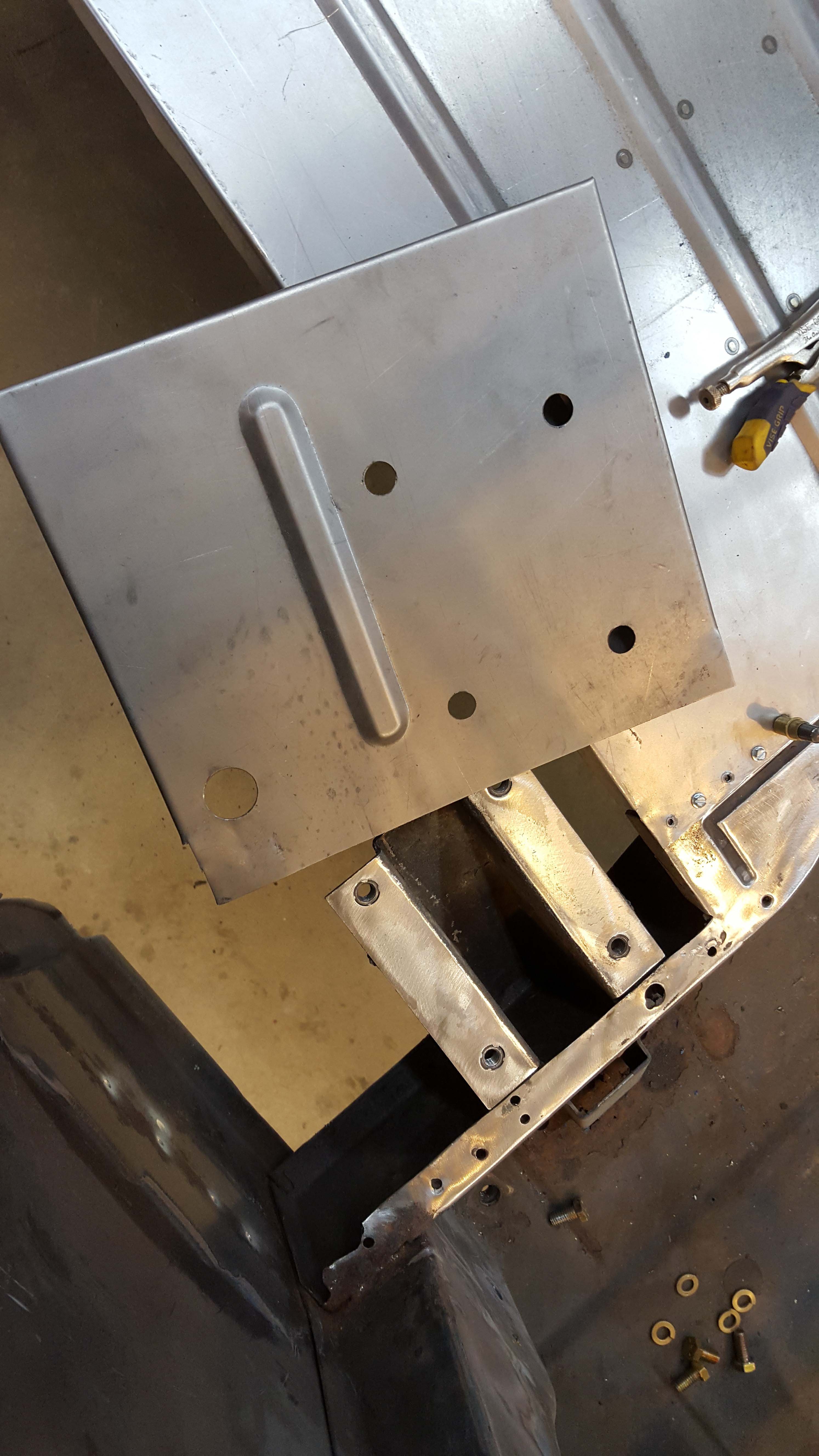

So I'm getting everything back from the blaster on Friday and I went ahead and ordered the panels from Classic that I already know I need, namely the ones under the roll bar mounts. I'm an ok welder but this will be my first crack at auto body sheet metal patching. My question is, do I leave the folded over lip on the panels or cut them off? That might be a dumb question but I just want to make sure I approach this the right way.