My CJ-7, which was the "donor" vehicle, had already had a YJ-tub swapped in '98.

Originally posted 9/4/10:

Finally have the firewall stripped from the orange carcass. I'm rebuilding and properly sealing the heat/air boxes and POR-15ing all the metal parts, as well as the swing-pedal assembly. The steering column I rebuilt when I installed it in 2000, so I'm not going to mess with it again. I do need a new u-joint for my Borgeson shaft. I'll post before and after pics soon.

Also have the auxilliary fuel tank and pump installed.

EDIT: pics added

Firewall stripped from the carcass.

Air/heater boxes out.

I removed all the metal components, including the internal flappers, and drilled out the rivets for the brackets, to POR-15 everything and add a top-coat of Hammerite for effect. All the rivets that I removed were replaced with aluminum, but the rivets that hold the actual boxes together were left since they seemed fine. The two halves of the defroster duct (not the accordian part) were held together with steel staples, which were replaced with aluminum rivets. All the plastic seams were sealed with a thin bead of black RTV.

I replaced the heater core about six years ago, and I upgraded the blower motor to the Chevy C/K style in 1999 or 2000. All the flappers were POR-15'd, and I replaced all the "sponge" seals with a rubberized foam. The plastic housing was sealed to the steel backing-plate by some dry putty garbage, which I stripped off and replaced with a new self-adhesive rubberized weather seal.

Completely reassembled housing ready for install with all new hardware, most of which is stainless. I love POR-15! I also had to drill and tap a replacement stud into the backing-plate.

I didn't take a good "before" shot of the swing-pedal assembly, but I can assure you it was completely rusted. Only the pedals themselves still had some paint. I actually think that AMC didn't bother to paint the brackets. Everything was POR-15'd and painted with Hammerite except for the pedals themselves which looked good, so they were prepped and painted with Hammerite only.

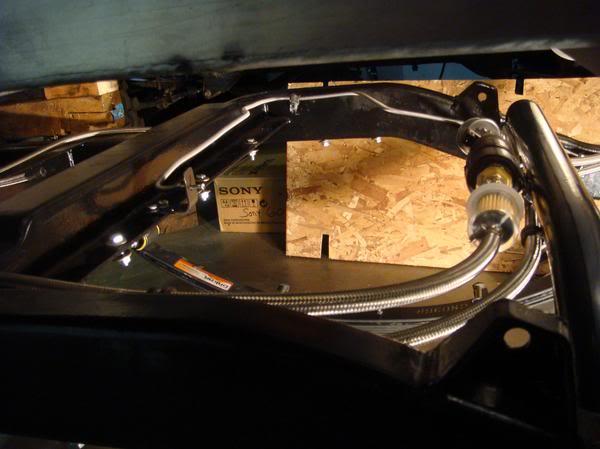

Auxilliary fuel tank with Jeep sending-unit and Jeep check-valve installed. Fat******* hooked me up with the custom tank, and Sleddy helped with the odd-sized hole needed for the check-valve.

Fuel tank installed. I haven't cut the hoses yet since we're still working on where/how the filler will mount.

at the thought of being able to build one from the ground up like this.

at the thought of being able to build one from the ground up like this.