Starting to make some noticeable progress which always helps with the motivation. The process of setting up new gears is actually lot less complicated than I originally thought. Once you understand the basic principles, its mainly just tedious work (as long as you have the right tools).

Since my last post I've gotten the NT AMC 20 fully assembled with a Tru-Trac, new 4:10 gears and all new seals/bearings. I also cleaned/replaced a few parts in the drum brakes but forgot to take any pictures. This setup is ready to swap out under my CJ5. Should make a pretty substantial difference since I am currently running 2:73 gears with 33" tires and a 3-speed (on long steep hills I have to downshift to 1st gear).

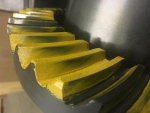

Earlier this week I got the NT Dana 30 dialed in with the correct shim measurements to set the pinion depth and backlash. I just need to pull off the setup bearings and races and do a final assembly with the new parts. A note to anyone who might be doing this in the future, check your installation kit before you get into it and make sure you have the oil slingers and oil baffle included. I bought a R&P + installation kit from G2 and they did not include these parts or the inner axle seals (which likely need to be replaced too). The NT Dana 30 is already painted so once I get it all put back together its ready for the CJ 5 as well.

The WT AMC 20 for the Scrambler is stripped down and sandblasted. I'm hoping to get the new gears installed in it this weekend. I also have to mount new spring perches that I got from Barnes 4WD since the PO had it setup for SOA. Additionally, I plan on converting the rear to disc brakes. Shout out to mhinchliffe for passing along the part numbers he used on his disc brake conversion.

Tonight, I got the WT Dana 30 completely stripped down and cleaned. It was gross to say the least. Hopefully we'll have some decent weather this upcoming week so I can get the housing sandblasted.

I'm glad I follow this forum because I had to use a trick I learned from reading through countless threads. I stripped one of my brake caliper retaining bolts when I was tearing down the axle but I was able to weld a nut onto the bolt head and use my big 3/4" drive impact to finally get it out.

1 axle down, 3 to go. Should be pretty good at this by the time I'm done.