This is the Warn stud kit:

The problem - the non threaded portion of the stud between the two threaded ends has a smaller OD then the threads, so the the studs will not fit tightly inside the bolt holes in the lock in hubs. This will allow motion, and looseness:

If you Google this Warn part number all the pictures show a fat center section. That is how they used to be, not anymore.

Typical picture, note the center section.

Warn External Hub Stud Kit - For Two Hubs.<br><br>Replaces the bolts that are normally used on your 1971-80 Scout II, Terra or Traveler and 1974-75 Pickup, Travelette or Travelall.<br><br>. Studs do not have the tendency to loosen like bolts do.<br><br>

www.ihpartsamerica.com

Here is an online review:

Warn Stud kit for locking hubs6 months ago

Not as pictured. Picture shows enlarged diameter in the unthreaded section between the two threaded ends of the studs, the set I received don't have this, actually smaller diameter than the threads. My wheel hubs have counterbores that extend about 3/8" into the hubs before female threads start. The shoulder of the original bolts fit pretty snugly down into these counterbores. A lot of torque gets put on the studs/bolts. I will mark the locking hubs and wheel hub after installation, but have no doubts they are going to be moving slightly in relation to each other, eventually damaging the studs or the wheel hub threads.

GREGORY · Reviewed on Summit Racing Equipment

I bought these studs from McCaster-Carr, probably not the best choice, but they are cheap. Note the fat OD center section, this is what you need:

I do not have a loose wheel hub to play with right now. BUT, if the female threads in the hub bodies do not start until about 3//8" deep, these could work. Long threaded end into the wheel hub. Part of the larger OD center in wheel hub, the other part fits securely into the lock in hub bolt holes. The short threaded end can take a metal self locking nut, and the OEM center cap should clear. I will have to experiment and see. I might need a slightly different stud, but you can get the idea.

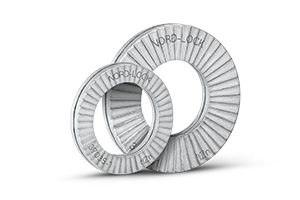

The Nord-Lock washers:

These fancy washer look promising/interesting.

IMO, the Warn stud kit is a waste of money. The included studs would be worse than bolts IMO.

Whenever I pull the front end apart on either my Green Scrambler/Spring Special, I will investigate this some more. I am pretty sure I can find the correct grade/length/thread pitch/fat center section stud on McMaster-Carr.