Picked up a used throttle body this weekend from my buddy Steven, thanks again:

On this used one, the threads on the return line were a bit munched, but I was able to save it. These parts are really crappy:

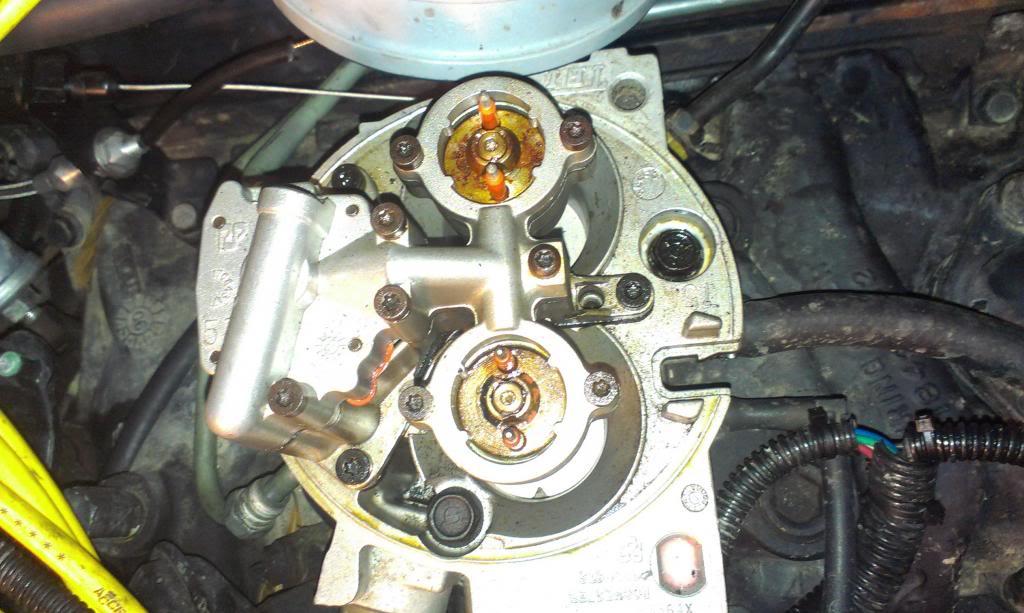

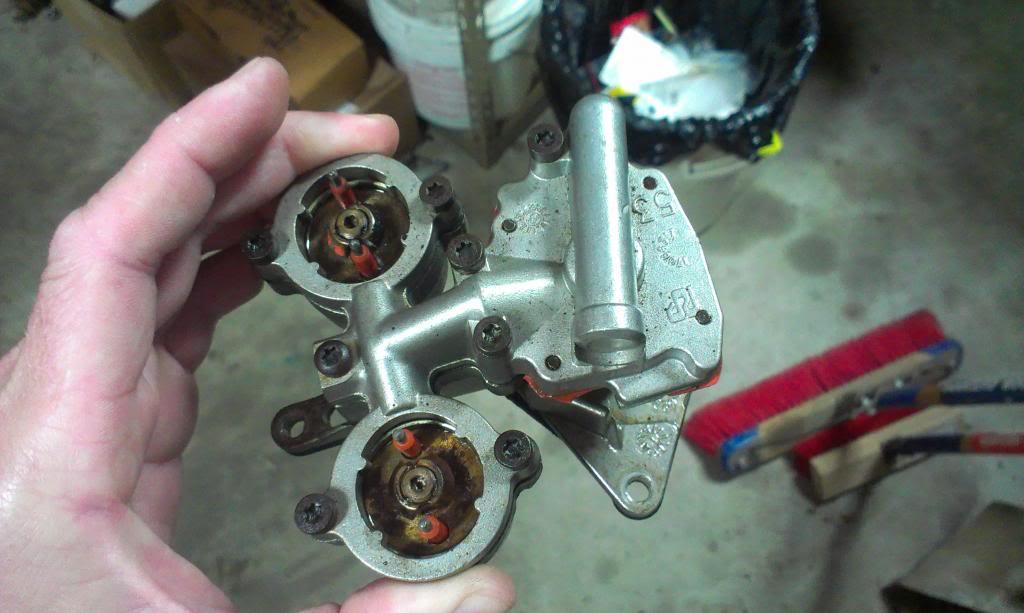

I am not going to do a step by step, but it is pretty easy to take the throttle body apart. You remove these screws/gaskets/seals, and the upper injector pod separates from the main injector pod:

Quick picture of the injectors, and their associated spacers/seals. Basically, I transferred all of my good parts to the used injector pod housing. Since all my parts are new, I was able to reuse all of the original gaskets. But, if you are messing with an older unit, I would advise buying a rebuild kit which will include all new seals/gaskets, just like a carb kit.

Quick pictures of the new to me dirty part, before cleaning:

And after a soak in the gallon of carb cleaner, good as new:

I also was able to use the used brass parts off of the junk throttle body. The threads on these two parts were perfect. Please note - each one of these brass parts has a seal that goes inside the injector pod BEFORE you thread them in. If you leave the seals out, the lines will leak.

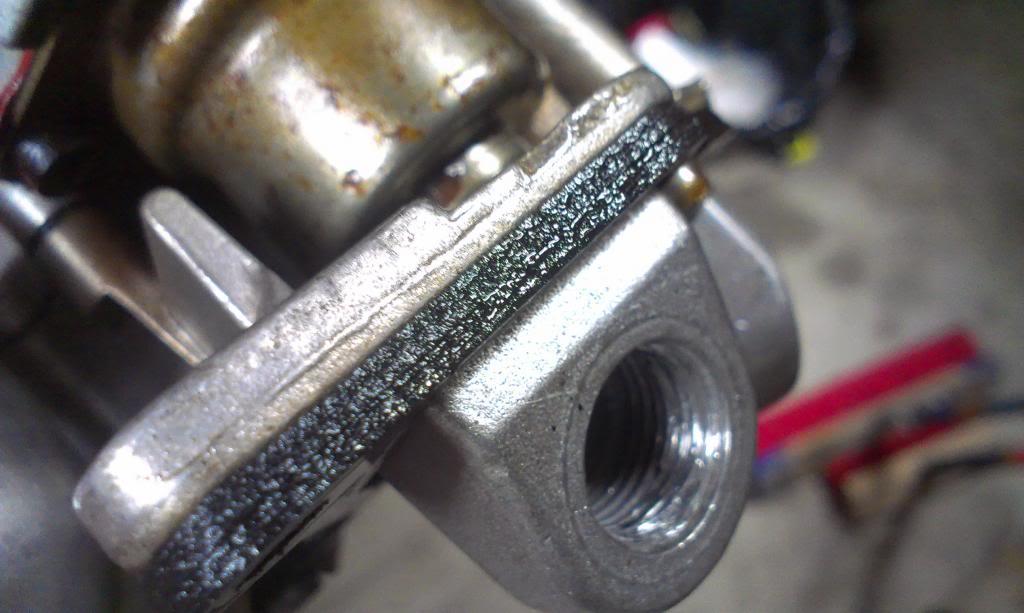

Quick picture of the stripped out threads in my leaking part:

And back together, running great, no leaks!!!!

Well, that was a bunch of work. In my opinion, if you ever have to remove/mess with these original GM TB fuel lines, use the utmost care. The combination of brass/aluminum threaded parts is a disaster waiting to happen. This fact, coupled with the issue of using the stock metal fuel lines, which are a pain to get lined up correctly, well be careful!!!

But, all the drama was worth it. No more smoke out the tail pipe, so the valve stem seal replacement was not for naught.

The last big "repair" that I need to make is to my duct taped up floor shifter plate, hope that is easier then this!!!!

That's it for now.