mhinchliffe

CJ-8 Member

- City

- W-S

- State

- NC

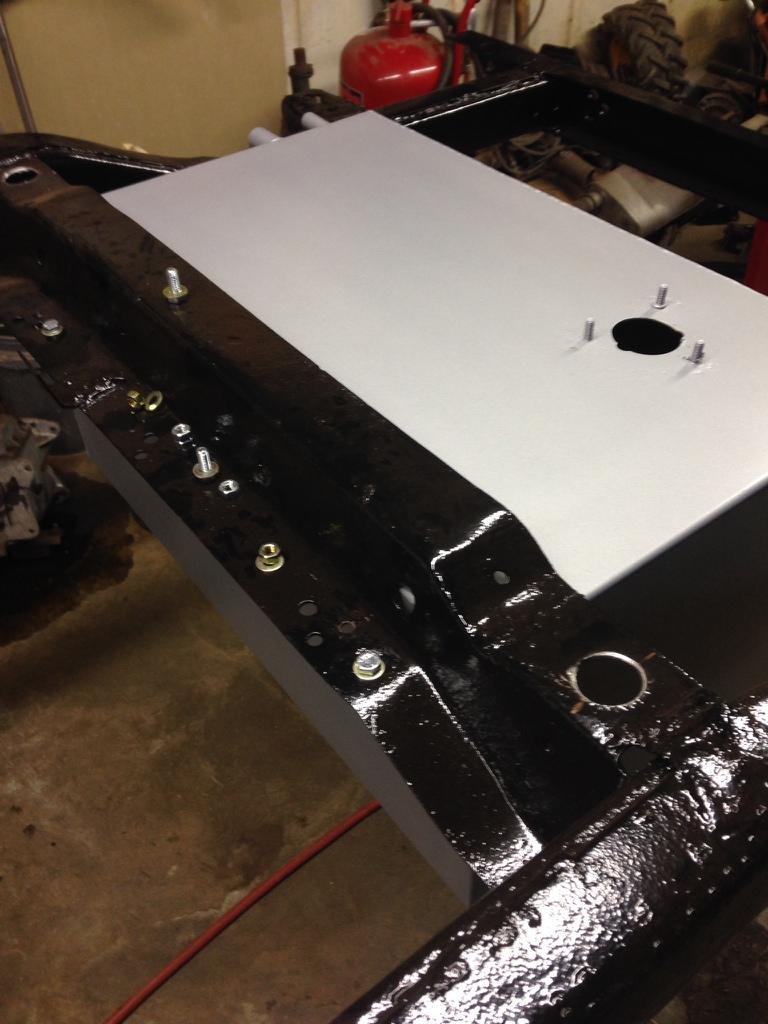

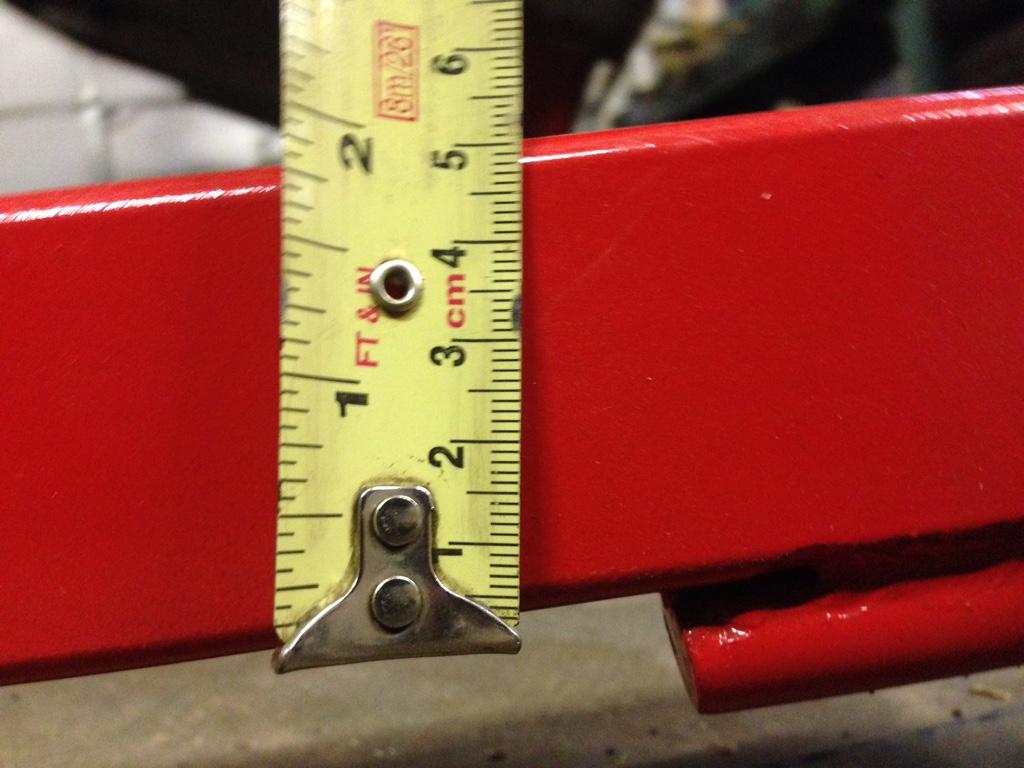

Here's what it's going to look like with the Gr8 fasteners on the gloss black frame.

Next on the list is the gas tank prime and paint, hard lines and axles

Next on the list is the gas tank prime and paint, hard lines and axles