- City

- Biloxi

- State

- MS

Looks like black oak leaves, not found in AZ/CA but is common in the SE.

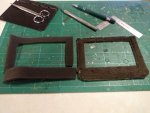

The sealant was probably an effort to keep any leaks from spilling all over the floor next time. The rust...well, they were never really painted well to begin with, and a leaky core with hot air blowing around would be a good place for it to start.

Yep, the oak leaves are from my yard LOL

I am "assuming" the previous owner in Nevada changed the heater core, just never hooked it up

I was kind of thinking that maybe the anti-freeze, over time, could strip the paint? You are correct on the quality of the paint, no primer, just paint directly to the bare metal. But, that's probably all I'm going to do to repaint it - sand off the rust, hit it with some black spray bomb.

I was kind of thinking that maybe the anti-freeze, over time, could strip the paint? You are correct on the quality of the paint, no primer, just paint directly to the bare metal. But, that's probably all I'm going to do to repaint it - sand off the rust, hit it with some black spray bomb.